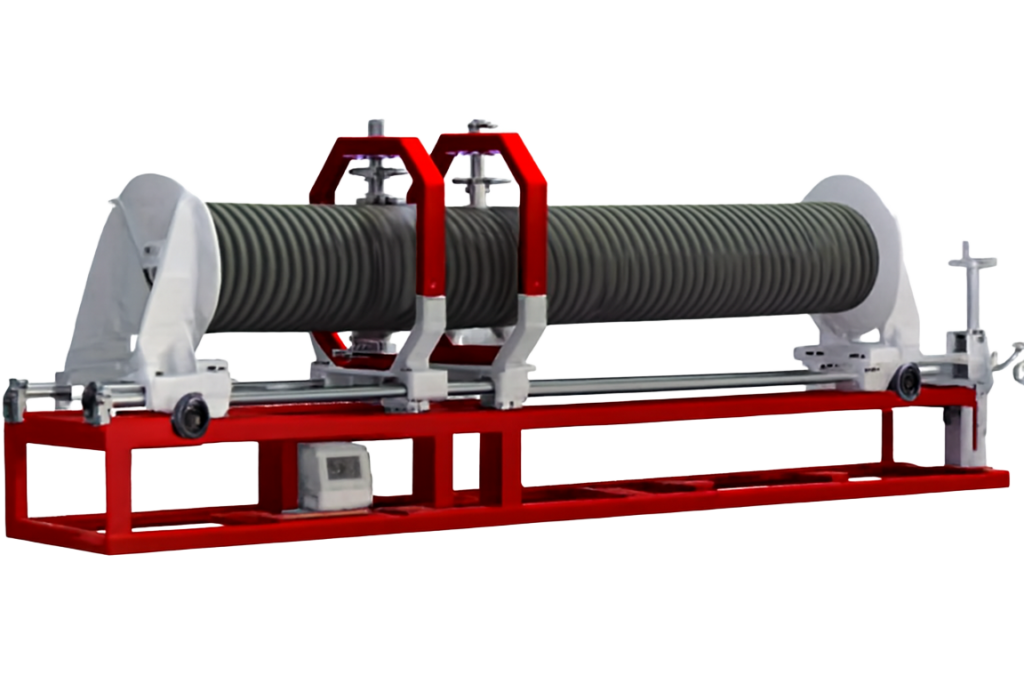

The crack growth tester from Amin Polymer is an essential tool for evaluating the mechanical integrity of polymer materials under repeated stress. Designed for fatigue crack growth testing, it measures how cracks initiate and propagate, providing critical data for industries like automotive, aerospace, and construction. Amin Polymer Export to GCC and the Middle East Countries focuses on delivering these advanced systems to regions where polymer applications are booming, ensuring compliance with global standards.

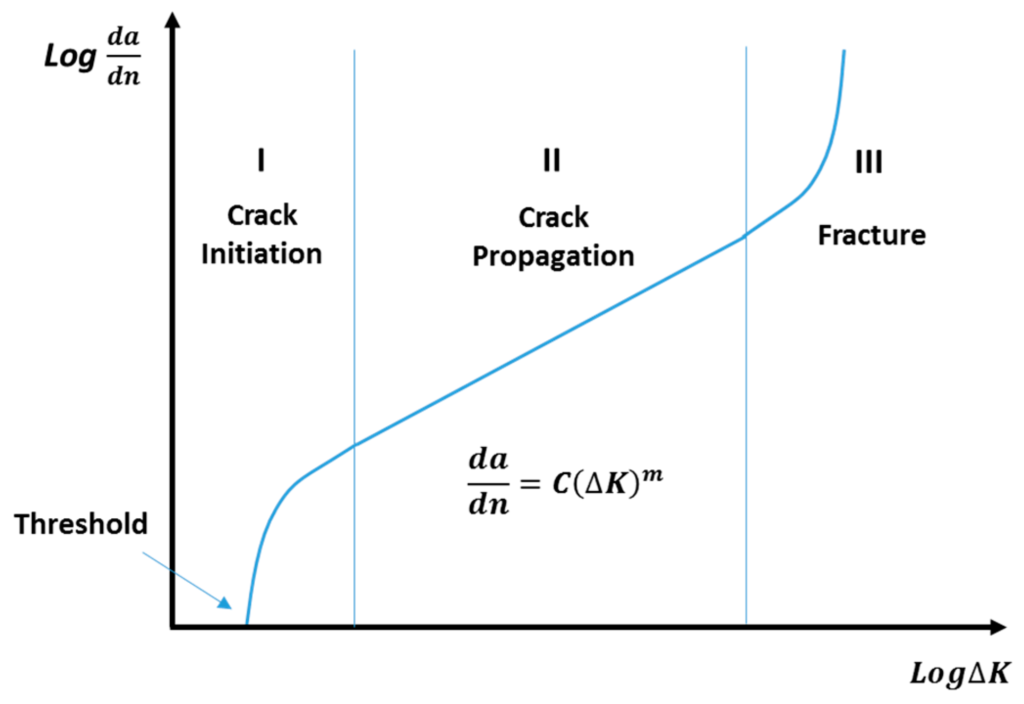

This tester simulates real-world conditions through cyclic loading, allowing engineers to predict material failure via crack growth rate testing. By incorporating crack growth retardation analysis, it helps in optimizing polymer formulations for longer service life. Amin Polymer's crack growth tester stands out for its precision in crack growth stages assessment, making it ideal for creep crack growth testing in harsh environments.

Commercially, investing in Amin Polymer's equipment means reduced downtime and enhanced product reliability. Our testers support slow crack growth rate tests, crucial for pipeline and packaging sectors in the Middle East. With features like automated crack depth measurement, users can generate accurate crack growth curves, aiding in data-driven decisions.

Request a Quotation from Amin Polymer to explore how our crack growth test solutions can elevate your operations. Backed by years of innovation, Amin Polymer ensures every unit undergoes rigorous quality checks, building trust among exporters and manufacturers.