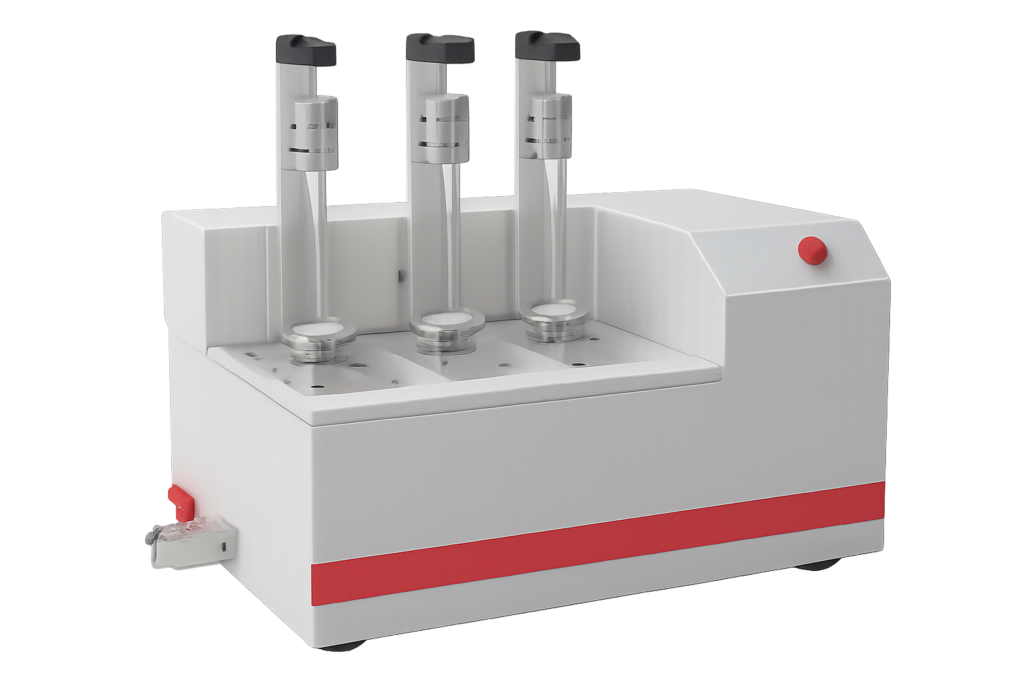

The HDT–VICAT testing machine is an essential tool in the polymer industry, designed to evaluate the thermal properties of materials under controlled conditions. At Amin Polymer, we pride ourselves on manufacturing state-of-the-art hdt/vicat testing machines that combine cutting-edge technology with user-friendly interfaces. These devices, including our automatic vicat apparatus, are crucial for determining how polymers behave when exposed to heat and mechanical stress. By measuring key parameters, the vicat tester helps manufacturers predict material performance in real-world applications, ensuring products meet stringent quality requirements.

Amin Polymer's commitment to excellence shines through in our vicat machine lineup, which includes models equipped for both Heat Deflection Temperature (HDT) and Vicat Softening Temperature (VST) tests. The automatic vicat machine streamlines operations, reducing human error and increasing throughput. In the context of Amin Polymer Export to GCC and the Middle East Countries, these machines are particularly valuable for industries like construction, automotive, and packaging, where polymers must withstand high temperatures. Our testing vicat solutions provide accurate data on softening points, aiding in material selection and formulation.

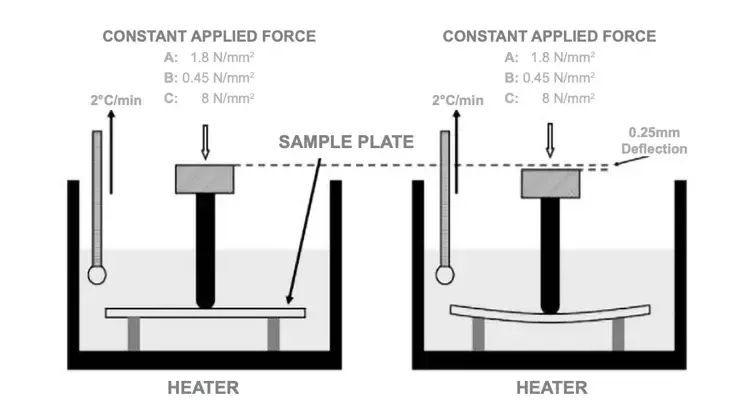

Furthermore, the vicat hdt tester from Amin Polymer integrates advanced sensors for precise temperature control and deflection measurement. This ensures that every test, whether it's a vicat needle test or a full hdt vicat testing machine run, yields reproducible results. Industries relying on thermoplastics benefit immensely from understanding deformation behaviors, preventing failures in end-use products. Amin Polymer's automatic vicat apparatus price is competitively positioned, offering exceptional value without compromising on features like digital displays and automated data logging.

The purpose of the HDT–VICAT testing machine extends beyond basic testing; it supports research and development by providing insights into polymer mechanics. For instance, the vicat test method allows engineers to assess penetration resistance under load, while HDT evaluates bending under heat. Amin Polymer Export to GCC and the Middle East Countries facilitates access to these tools, empowering regional businesses to compete globally. Our vicat testing equipment is built to last, with robust construction that withstands rigorous lab environments.

In summary, the overview of our HDT–VICAT testing machine highlights its role in enhancing product reliability. Amin Polymer ensures that each unit, from the basic vicat tester to advanced models, meets the needs of diverse applications. By choosing Amin Polymer, clients gain a partner dedicated to innovation and support in polymer testing.