The dynamic mechanical thermal analyzer (DMTA) from Amin Polymer is a sophisticated instrument for dynamic mechanical analysis of polymers, measuring viscoelastic behavior under oscillatory stress across temperature and frequency ranges. This dma dynamic mechanical analyzer excels in characterizing materials for automotive, aerospace, and construction sectors dominant in the Middle East. Amin Polymer Export to GCC and the Middle East Countries supplies these dynamic mechanical analysis machines to support innovative polymer applications in extreme conditions.

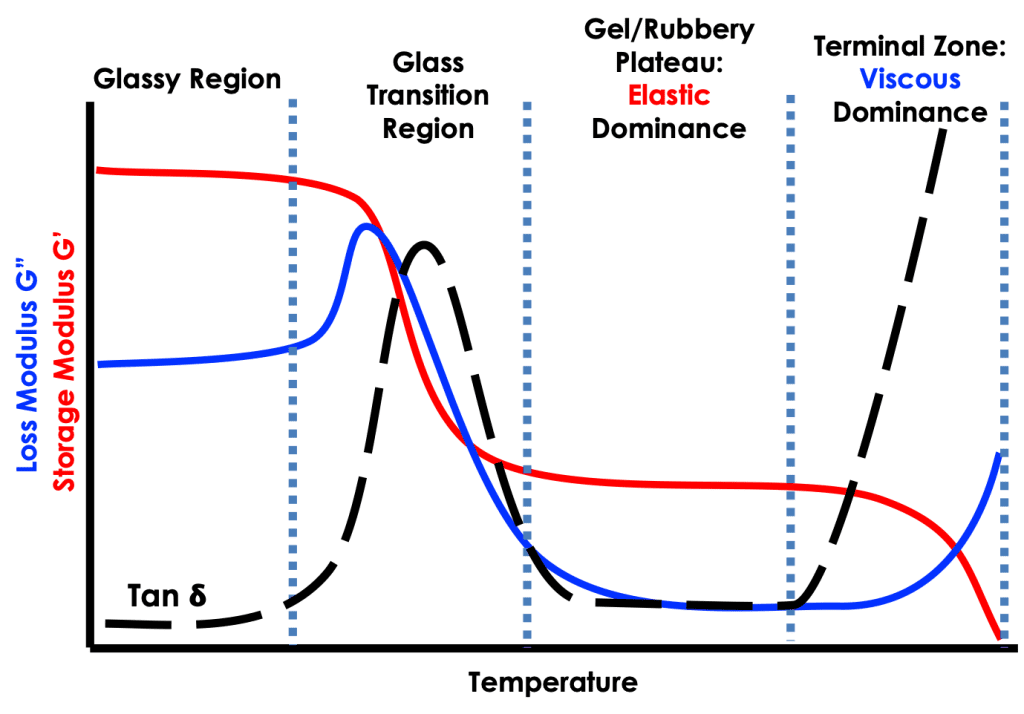

By applying sinusoidal deformation, the DMTA captures storage modulus (elastic response), loss modulus (viscous dissipation), and tan delta (damping), essential for understanding glass transitions and secondary relaxations. Amin Polymer's dynamic mechanical thermal analyser incorporates advanced controls for accurate dmta analysis of polymers, aiding in material optimization against vibration and thermal cycling.

Commercially, investing in Amin Polymer's dynamic mechanical analyzer for sale means enhanced product longevity and performance, reducing failures in harsh environments. It supports frequency sweeps for master curve generation, predicting long-term behavior via time-temperature superposition. In growing markets, dmta analysis reveals filler effects and compatibility in composites.

Request a Quotation from Amin Polymer to access affordable dynamic mechanical analyzer price options with comprehensive software for data visualization. Our equipment handles diverse modes like tension, bending, and shear, versatile for films, fibers, and rigid samples.

The purpose includes R&D for new formulations and quality assurance, where dynamic thermal analysis detects subtle transitions missed by other techniques. With Amin Polymer Export to GCC and the Middle East Countries, clients gain on-site training, ensuring seamless integration. Overall, this dynamic mechanical thermal analysis dmta combines technical depth with commercial value, empowering manufacturers using dynamic mechanical analysis equipment to achieve superior material insights and market competitiveness. Amin Polymer's dedication to innovation makes our dma dynamic mechanical analyzer a trusted choice globally.