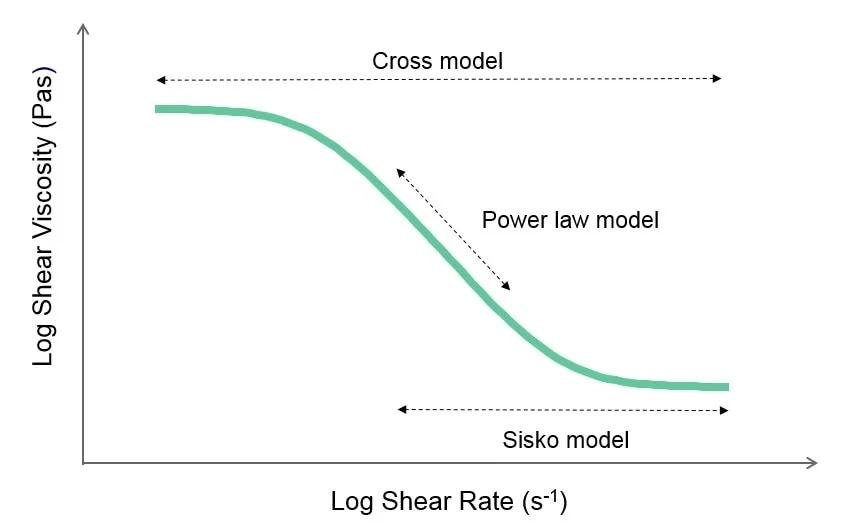

Amin Polymer specializes in rheometers that are indispensable for characterizing the flow and deformation behavior of polymers under various conditions. A rheometer, unlike a simple viscometer, measures complex rheological properties such as viscosity, elasticity, and shear thinning, making it essential for non-Newtonian materials like polymer melts and solutions. The difference between viscometer and rheometer lies in the rheometer's ability to apply controlled stress or strain, capturing dynamic responses. For instance, a brookfield rheometer or rheometer brookfield excels in low-shear viscosity, while a capillary rheometer diagram illustrates high-shear flow through a die, simulating extrusion processes.

In polymer industries, rheometers help optimize formulations by analyzing how molecular weight and branching affect flow. The function of rheometer includes determining shear rate dependencies, crucial for processing like injection molding. Amin Polymer's offerings, such as the dynamic shear rheometer and oscillatory rheometer, provide insights into viscoelasticity, aiding in quality assurance. Our capillary rheometer price is competitive, ensuring accessibility for labs in the GCC region.

Commercially, investing in Amin Polymer's rheometers reduces production defects by predicting material behavior, saving costs and enhancing product reliability. The rheometer and viscometer difference is key: rheometers handle complex fluids where viscosity varies with shear. For rubber compounds, our oscillating die rheometer measures cure kinetics, as shown in rheometer analysis. Amin Polymer Export to GCC and the Middle East Countries delivers these instruments with robust support, building trust through precision engineering.

Whether you're using a plate plate rheometer or parallel plate rheometer for shear tests, or a mixer torque rheometer for compounding, Amin Polymer ensures durability. The future foundation rheometer from our line integrates advanced sensors for real-time data. Request a Quotation to explore how our rheometers, including rheometer cone and plate setups, can elevate your operations. In the Middle East's growing petrochemical sector, these tools are vital for innovation.

Our modular compact rheometer allows easy upgrades, while the discovery core rheometer offers high-end research capabilities. Dynamic shear rheometer price varies, but Amin Polymer provides value-driven options. Rheometer calibration services are included, ensuring long-term accuracy. By choosing Amin Polymer, you gain a partner committed to advancing polymer technology through reliable rheometry.