Amin Polymer offers state-of-the-art melt volume rate testers designed to evaluate the flow characteristics of thermoplastic polymers. The melt volume rate, often abbreviated as MVR, is a critical parameter that quantifies the volume of molten polymer extruded through a standardized die under specific temperature and load conditions, typically expressed in cm³/10 min. This measurement provides insights into the polymer's viscosity and processability, distinguishing it from melt flow rate (MFR), which is mass-based in g/10 min. Understanding melt flow rate to melt volume rate conversion is essential, as MVR accounts for density variations, making it more suitable for certain applications.

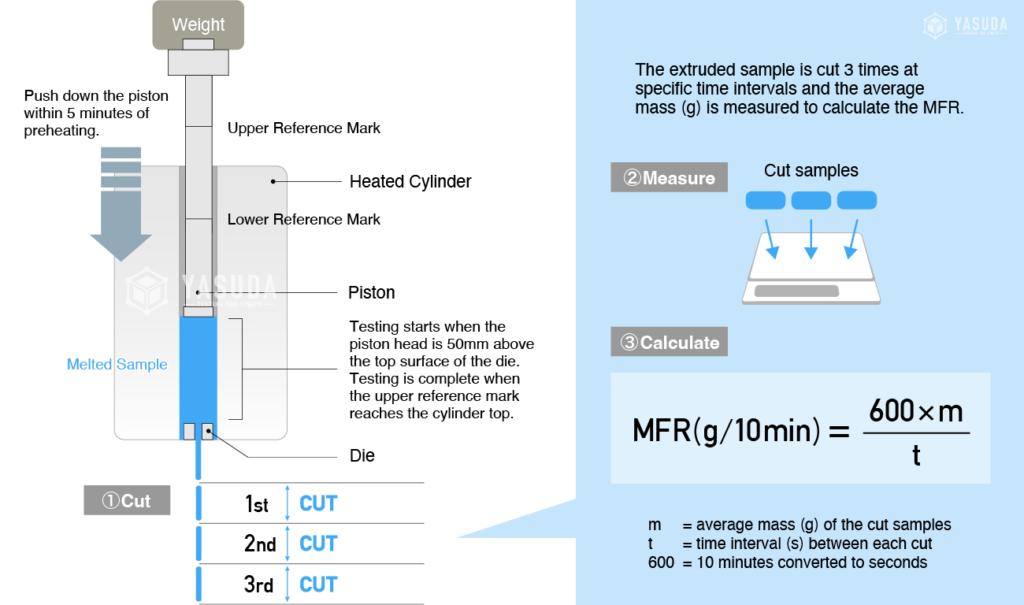

In the polymer industry, the melt volume flow rate definition highlights its role in assessing how easily a material flows during processing like injection molding or extrusion. Amin Polymer's testers ensure precise melt volume rate formula application, where MVR = (volume extruded / time) × 10, helping manufacturers optimize formulations. For instance, a higher melt volume rate unit indicates lower molecular weight and better flow, crucial for high-speed production.

Amin Polymer Export to GCC and the Middle East Countries caters to booming petrochemical sectors in regions like Saudi Arabia and the UAE, where accurate melt volume index testing supports the development of durable plastics for construction and packaging. Our devices are engineered for reliability, featuring automated controls that minimize human error and deliver consistent results. What is melt volume flow rate? It's the volumetric flow under standardized conditions, and Amin Polymer's equipment excels in measuring it, building trust through robust construction and compliance with global standards.

Commercially, investing in Amin Polymer's melt volume rate vs melt flow rate capable testers reduces material waste and enhances product quality, leading to cost savings. We provide comprehensive support, including training, to encourage seamless integration into your operations. The melt volume-flow rate definition underscores its volumetric nature, and our testers handle a wide range of polymers, from polyolefins to engineering resins.

Whether you're calculating melt volume rate for quality control or comparing mvr melt volume rate across batches, Amin Polymer stands as a partner in innovation. Request a Quotation to explore how our solutions can elevate your polymer exports and manufacturing prowess in the competitive Middle East market.