Amin Polymer offers a comprehensive range of hardness tester machines designed for evaluating the mechanical properties of polymers. The hardness tester definition encompasses devices that measure a material's resistance to indentation, crucial for quality assurance in manufacturing. Our hardness tester durometer models, including the hardness tester shore a and hardness tester shore d, provide accurate readings for rubber and plastic materials. As part of Amin Polymer Export to GCC and the Middle East Countries, we supply hardness tester portable units that are ideal for on-site testing, ensuring portability without compromising precision.

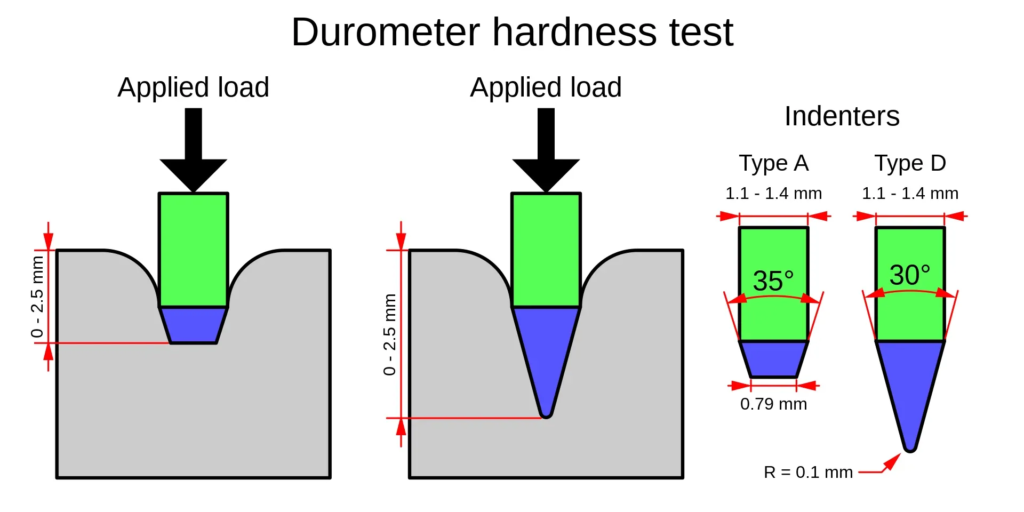

The objective of using a hardness tester is to determine the hardness test value, which indicates how well a polymer can withstand deformation under load. This is essential in industries like automotive, construction, and packaging within the Middle East. Amin Polymer's digital hardness tester and electronic hardness tester feature advanced technology for consistent results. The hardness tester principle relies on applying a specific force via an indenter and measuring the depth or size of the impression.

Incorporating keywords like hardness tester for plastic and hardness tester for rubber, our products cater to diverse applications. The portable hardness tester machine from Amin Polymer is lightweight and user-friendly, with a digital portable hardness tester option that displays instant readings. For those seeking a material hardness tester, our range includes the shore hardness tester, which is versatile for various polymer types.

Amin Polymer ensures that every hardness tester apparatus meets international standards, building trust through rigorous calibration of hardness tester procedures. Our hardness tester calibration block and hardness tester calibration procedure guarantee accuracy, making our offerings reliable for export markets. The hardness tester working principle involves standardized methods to avoid errors, and our team provides a hardness tester manual with each unit.

In the context of Amin Polymer Export to GCC and the Middle East Countries, we emphasize commercial benefits such as competitive hardness tester machine price and hardness tester price options. Request a Quotation to discover how our digital hardness tester price fits your budget. With Amin Polymer, you get not just equipment but a partner in enhancing product quality through precise hardness testing of materials.

Our hardness tester uses extend to quality control labs, where the unit of hardness tester (typically in Shore units) helps in material selection. The types of hardness tester we export include automatic hardness tester and manual variants, ensuring flexibility. How hardness tester works is straightforward: select the appropriate scale, apply the indenter, and read the value. This simplicity, combined with our support, encourages businesses in the GCC to choose Amin Polymer for their needs.