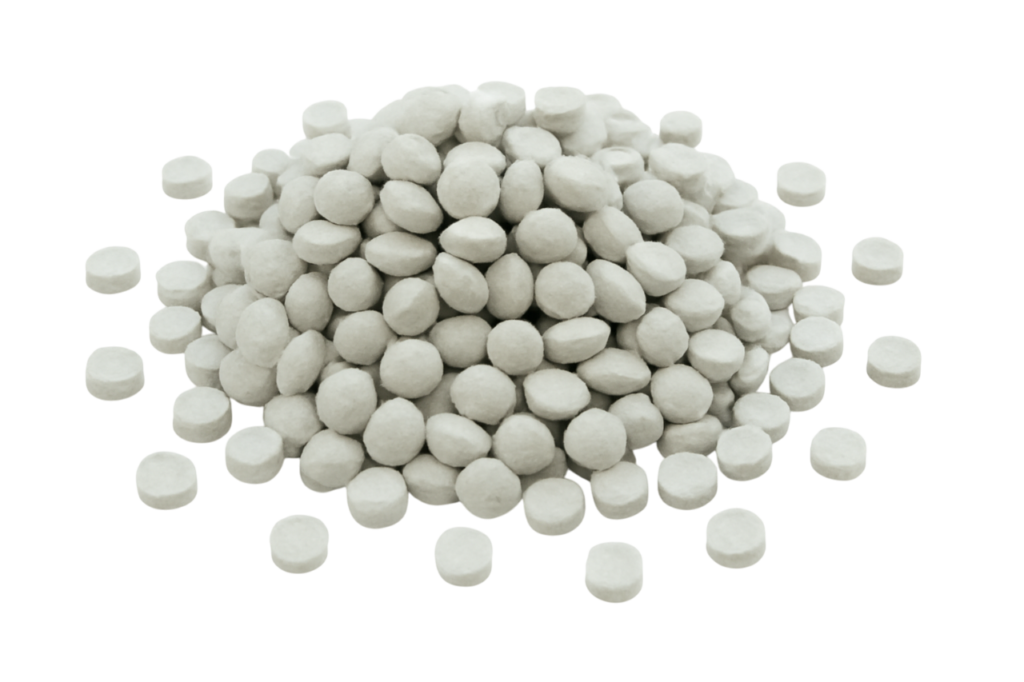

Amin Polymer specializes in high-quality polypropylene glass fiber reinforced compounds, tailored for demanding industries. As a leading provider, Amin Polymer ensures superior performance through advanced manufacturing. Our glass fiber polypropylene solutions enhance strength and durability, making them ideal for export. Amin Polymer Export to GCC and the Middle East Countries focuses on reliable supply chains, meeting regional standards. With fiberglass polypropylene expertise, we deliver compounds like glass filled polypropylene that outperform standard materials. Get in touch with Amin Polymer today for customized solutions in polypropylene with glass fiber.