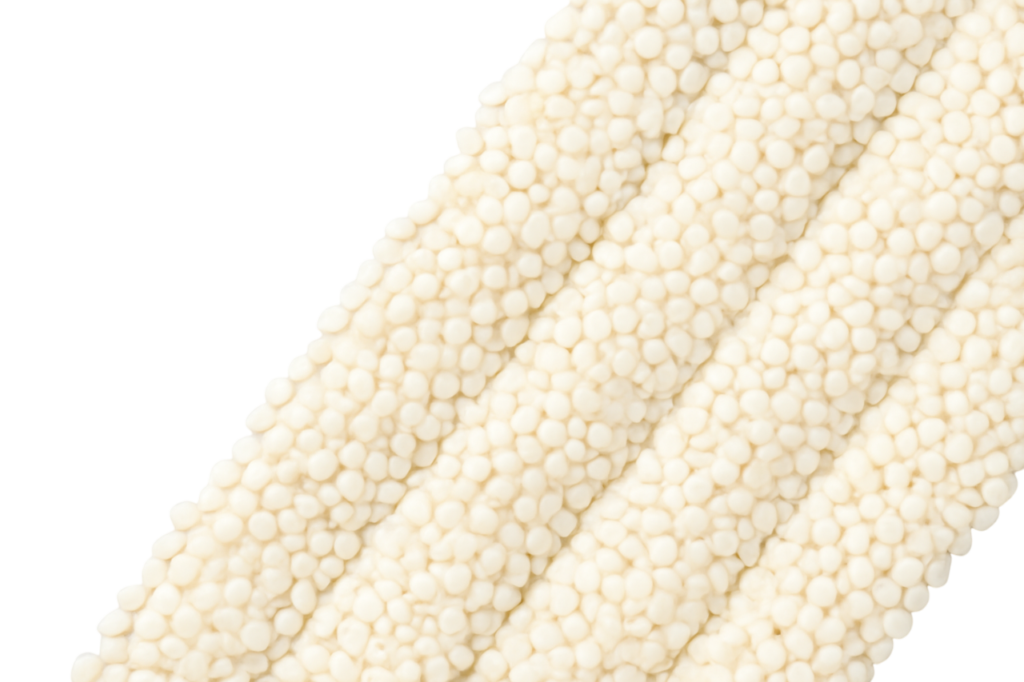

Amin Polymer's UV stabilizer masterbatches are versatile across industries requiring outdoor durability. They safeguard polymers in high-UV regions, aligning with UV stabilized HDPE, UV stabilized polyethylene, and UV stabilized polypropylene needs. From construction to everyday items, these additives prevent degradation in films, sheets, and molded parts. Amin Polymer Export to GCC and the Middle East Countries meets regional demands for UV stabilized HDPE sheet, pipes, and profiles, ensuring compliance and longevity.

UV Stabilizer Masterbatches in the Automotive Industry:

Shields exterior components like bumpers and trims from fading and cracking

Protects interior dashboards and door panels against sun-induced discoloration

Maintains mechanical integrity in under-hood parts exposed to heat and UV

Enhances longevity of lighting housings and seals with UV stabilized polycarbonate

Use of UV Stabilizer Masterbatches in Consumer Goods:

Preserves outdoor furniture and garden tools from brittleness

Extends life of toys, sporting equipment, and household items

Maintains vibrant colors in packaging and crates

Supports durable crates, drums, and water tanks in sunny conditions