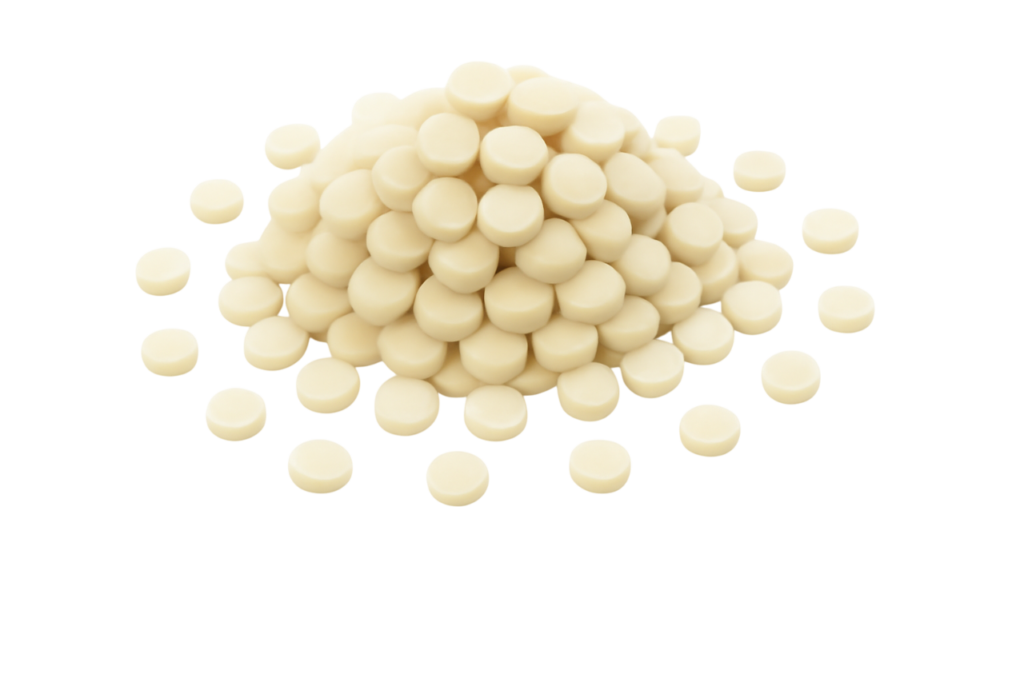

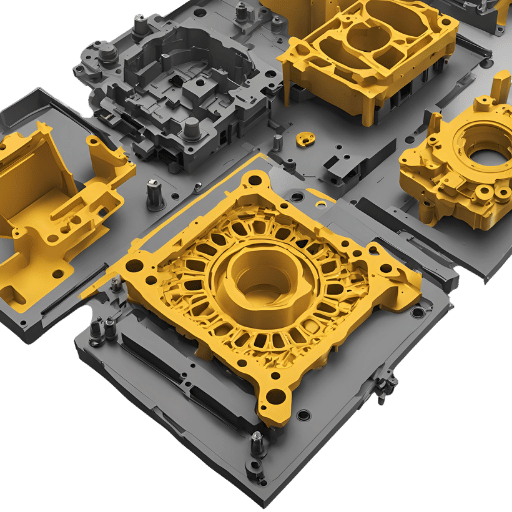

Amin Polymer excels in exporting acrylonitrile butadiene styrene ABS compounds, renowned for their durability and versatility. As a premier supplier of ABS material, Amin Polymer ensures top-tier ABS plastic material tailored for industrial needs. Our acrylonitrile butadiene styrene ABS plastic solutions deliver exceptional performance. Amin Polymer Export to GCC and the Middle East Countries guarantees reliable delivery, meeting regional demands. With expertise in what is acrylonitrile butadiene styrene, we offer competitive acrylonitrile butadiene styrene ABS price. Get in touch with Amin Polymer for superior ABS material plastic.