Amin Polymer provides a wide array of grades for automotive plastic components, categorized to suit specific needs. Technically, these grades feature tailored additives for properties like flame retardancy. Commercially, they enable customization, reducing lead times and costs in automotive plastic parts manufacturing process. Amin Polymer Export to GCC and the Middle East Countries includes all varieties, addressing regional automotive growth.

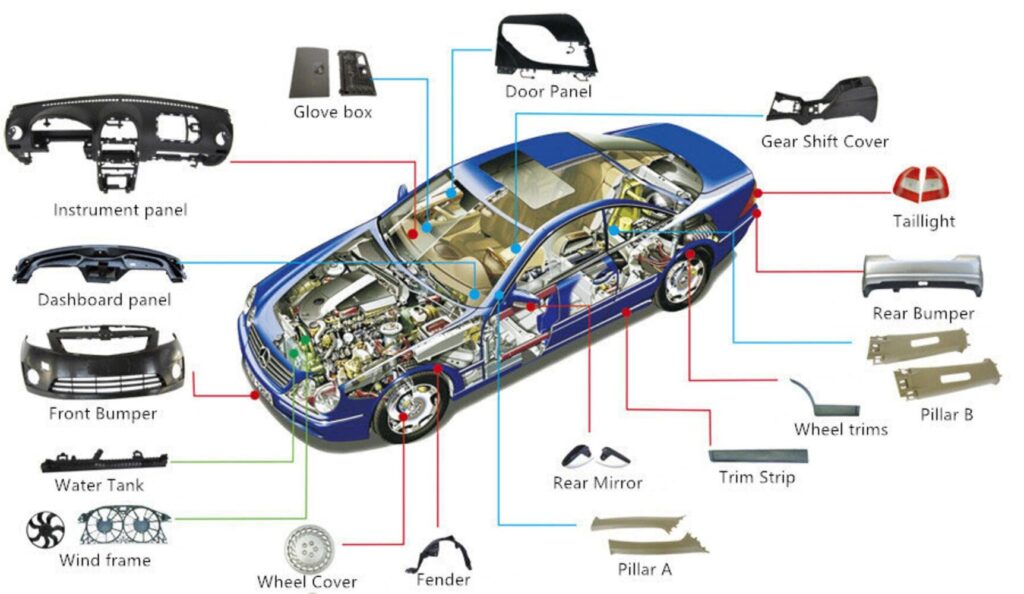

Industrial plastics: PE, PP, PVC, ABS, and PMMA offer cost-effective options for high-volume parts, with PP ideal for bumpers due to its impact strength.

PE for flexible hoses; PP for rigid bumpers; PVC for wiring insulation; ABS for durable dashboards; PMMA for clear headlight lenses, all offering affordability and ease of processing.

Engineering plastics: including UHMWPE, PA, POM, PET, and PC, deliver enhanced mechanical properties for demanding applications like gears and bushings. High-performance grades such as PVDF, PEEK, and PTFE excel in extreme conditions, providing low friction for engine components.

UHMWPE for wear-resistant liners; PA for strong bearings; POM for precise gears; PET for reinforced belts; PC for impact-proof windows, providing high strength and dimensional stability.