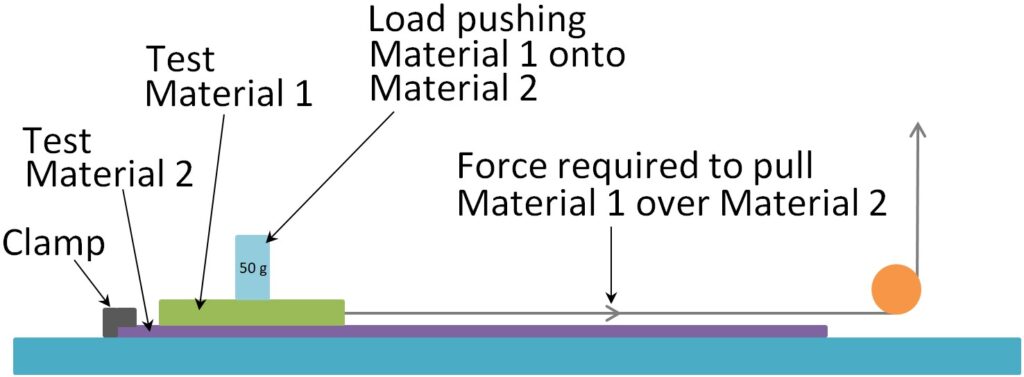

Amin Polymer is a premier exporter of advanced coefficient of friction (COF) testing equipment for polymer industries in the GCC and Middle East. Our coefficient of friction tester ensures precise static and dynamic measurements, essential for film quality control. Amin Polymer Export to GCC and the Middle East Countries delivers reliable coefficient of friction testing machines compliant with global standards. Trust Amin Polymer for innovative solutions in friction coefficient test procedures and equipment.