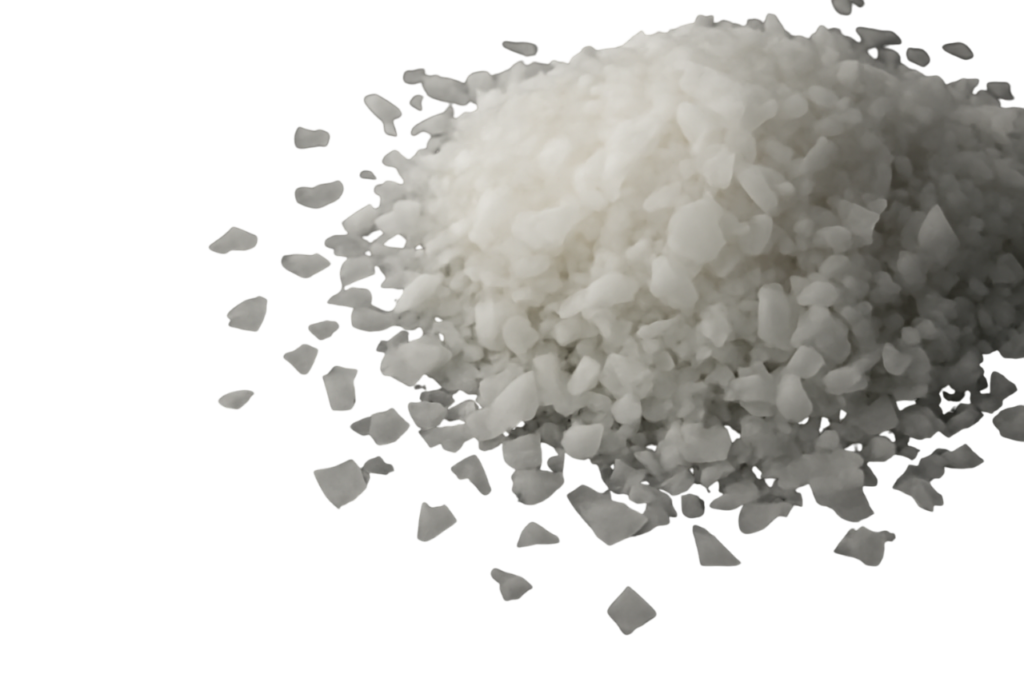

Amin Polymer stands as a leading exporter of high-quality polyethylene wax to GCC and the Middle East countries, serving industries from plastics to coatings. With consistent purity and performance, Amin Polymer Export to GCC and the Middle East Countries delivers reliable polyethylene waxes that meet global standards. Our competitive polyethylene wax price, combined with exceptional technical support, makes Amin Polymer the trusted partner for regional manufacturers seeking superior processing lubricants and additives. Get in touch with Amin Polymer for your supply needs.