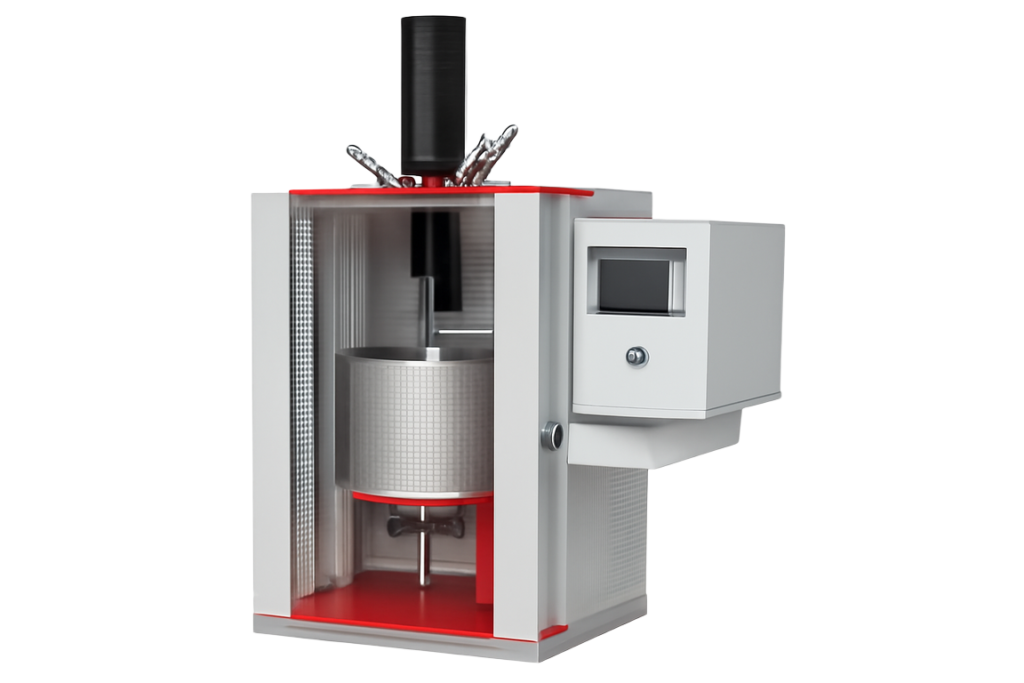

Operating a lab scale reactor from Amin Polymer involves systematic steps to ensure safety and accuracy. First, prepare the specimen, typically polymer precursors or samples, by measuring precise quantities. For instance, in a lab scale batch reactor, load monomers, catalysts, and solvents into the vessel. Secure the setup, including seals for lab scale pressure reactor models, to prevent leaks.

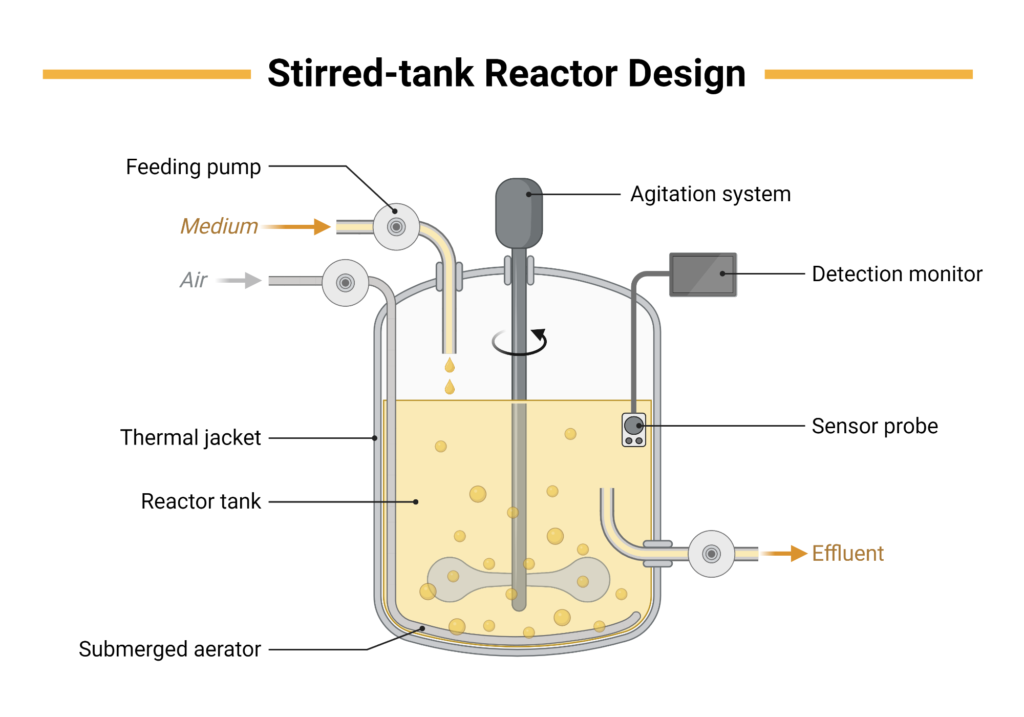

Initiate the reaction by setting parameters via the control interface. Amin Polymer's reactors feature intuitive software for monitoring. Heat the mixture using the jacket in a lab scale jacketed reactor, maintaining temperatures up to 300°C. Agitate with overhead stirrers to promote uniform mixing, especially in high-viscosity polymer applications.

Monitor progress through sensors that track pressure, temperature, and pH. In lab scale continuous flow reactor setups, feed reactants steadily while collecting products. Once complete, cool the system and extract the specimen for analysis. Amin Polymer Export to GCC and the Middle East Countries includes comprehensive manuals for these procedures, building user confidence.

Specimens vary from liquid monomers to solid polymers post-reaction. Our lab scale glass reactor allows visual inspection during the process. Request a Quotation from Amin Polymer to customize your setup for specific specimens like biodegradable polymers.