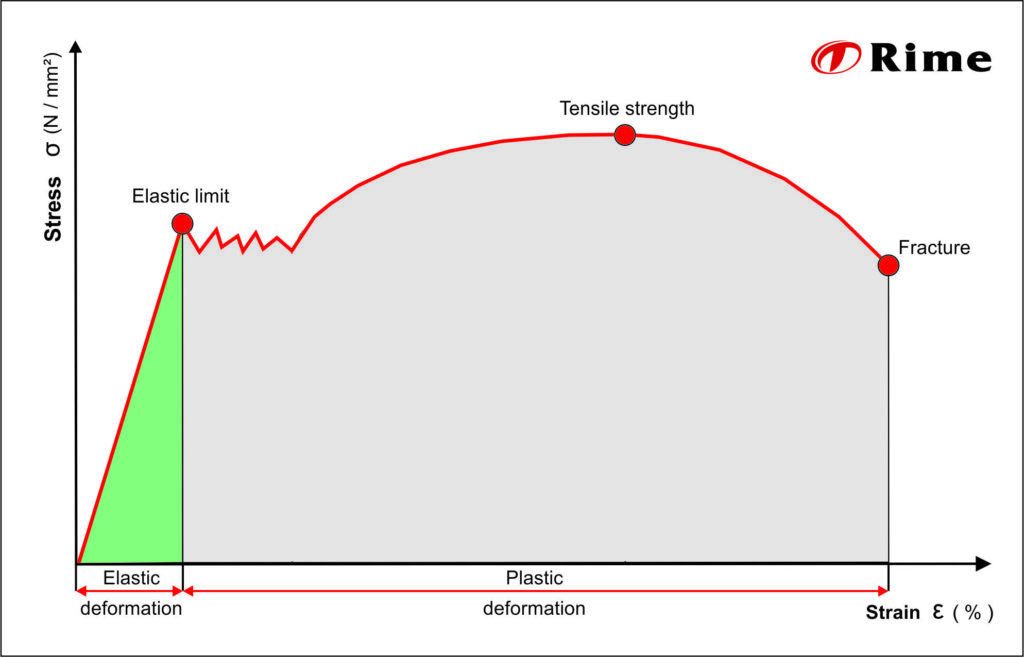

A Universal Testing Machine is a key method used to evaluate a material’s tensile strength by applying a uniaxial force until it breaks. The purpose of the tensile test is to determine properties like elongation, strength, and deformation behavior. It is essential for testing the durability of materials, alongside other tests like compression and bending tests, which help measure different mechanical properties.